The Plasma Arc Welding (PAW) and the cutting process was invented by Robert M.Gage in 1953 and patented in 1957. This process was unique because it could do precision cutting on both thick and thin metal. It is also capable of spray coating hardening metal on other metals.

Working Principle of Plasma Arc Welding

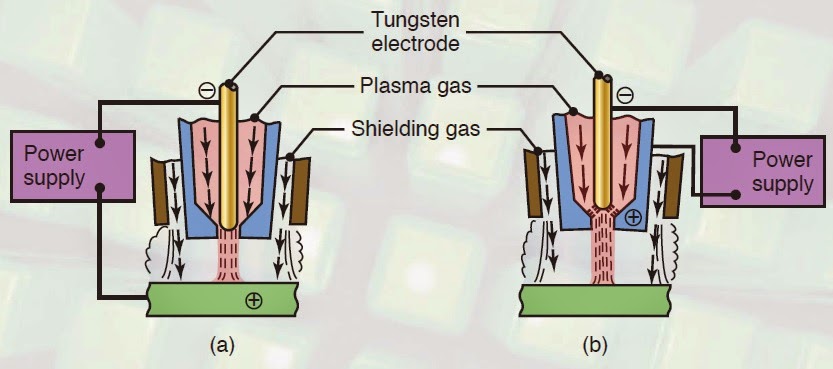

PAW is a process where a coalescence is produced by the heat which is developed from a special setup between a tungsten alloy electrode and the water-cooled nozzle (Non transferred ARC ) or between a tungsten alloy electrode and the job (transferred ARC) . This process employs two different gases for two different purposes –

- One gas is used to form the Arc plasma.

- Second gas is used to shield the arc plasma.

Main Equipment:

- Power supply: A DC power source with a drooping characteristic and an open circuit’s voltage of 70 volts or above is very much suitable for plasma arc welding.

Typical welding parameters:

Current: 50-350A

Voltage: 27-31 v

Gas flow rate: 2-40 l/minute

- High frequency generator and current limiting resistors: These both are used for arc ignition.

- Plasma torch: The torch has an electrode and water cooling system which saves the life of the nozzle and the electrode from melting due to excessive heat produced while welding.

- Fixture: It is required to avoid atmospheric contamination of the molten metal under bead.

- Shielding gas: An inert gas, either Argon, helium, or a mixture, is used for shielding the arc area from the atmosphere. Argon is more common because it is heavier and provides better shielding at lower flow rates.

Also Read:

- Resistance Welding – Principle, Working and Application

- Types of Welding Electrodes

- What is Welding Defects – Types, Causes and Remedies?

Working Concept of Plasma Arc Welding:

The process works by ionizing gas. when gas gets ionized, it can conduct electricity. The gas is used to transfer an electric arc to the piece of the job being welded. The gas can be argon plus a secondary gas helium which shields the arc weld puddle.

Working of Plasma Welding:

The plasma arc welding process is normally compared to the gas tungsten arc process :

- The plasma torch contains an electrode made out of tungsten fixed in a nozzle which is made of copper. The arc is started between the electrode and the tip of the nozzle. Then the arc or flame is transferred to the material to be welded.

- The small opening forces the gas to travel through a constricted opening or orifice. This concentrates the heat to a smaller area. This ability allows the welder to produce a very high-quality weld.

- The result is a process that gives higher welds speed, less distortion, more consistent welds, less spatter, and more control over the weld area.

The plasma welding process has two different modes that are:

- Non transferred arc mode: In non-transferred arc mode the current flow is from the electrode inside the torch to the nozzle containing the orifice and back to the power supply. It is used for plasma spraying.

- Transferred arc mode: In transferred arc mode the current is transferred from the tungsten electrode inside the welding torch through the orifice to the workpiece and back to power supply. It is used in welding metals.

Also Read:

- How Thermit Welding Process Works?

- Types of Welding Process – Everyone Should Know

- Difference Between MIG and TIG Welding

For a Better Explanation Watch the Video Given Below:

Advantages:

- Constricted opening or orifice gives you more concentrated heat in smaller area.

- It is more stable and does not gets deflected from the base metal.

- Plasma arc welding has deeper penetration capabilities and produces a weld.

- It gives high speed welds.

- Less distortion of base metals.

- More control on the small welding areas.

Disadvantages:

- Orifice replacement is necessary.

- It’s equipments are very much expensive.

- An individual needs more skills to use PAW.

- Nozzle gets melt which has to be change frequently .

Applications:

- It is used in manufacturing tubing (steel tubes)

- Used to weld small components of metal.

- Used to make butt joints of wall tubing.

- Used in thin electronic chips and medical setups.

Conclusion

Here we have discussed what is plasma arc welding, its main parts, working, advantages, disadvantages with application. I hope you have enjoed the post and if you found this piece of information valuable and useful then don’t forget to like and share it.