Arc welding is one of the most popular and versatile methods of welding used in various industries, from construction and automotive to manufacturing and repair. Its ability to join metals efficiently and effectively makes it an essential technique for many applications. In this blog post, we’ll dive into the details of arc welding, covering its fundamentals, types, equipment, applications, and safety considerations.

What is Arc Welding?

Arc welding is a process that uses an electric arc to melt and join metals. The arc is generated between an electrode (which can be consumable or non-consumable) and the base metal, creating intense heat that melts the metals at the welding point. Once the molten metal cools, it solidifies to form a strong, durable bond.

Basic Principles of Arc Welding

Electric Arc Formation:

The core principle of arc welding is the formation of an electric arc between the electrode and the workpiece. This arc generates temperatures as high as 6,000°C (10,832°F), sufficient to melt most metals.

Electrode:

The electrode serves as a conductor for the welding current and can be either consumable or non-consumable. Consumable electrodes melt and become part of the weld, while non-consumable electrodes do not melt and are often made of materials like tungsten.

Shielding:

To protect the molten weld pool from contamination by atmospheric gases (oxygen, nitrogen, and hydrogen), shielding is essential. This can be achieved through flux-coated electrodes, shielding gases, or a combination of both.

Arc Welding Equipment

1. Power Source:

Provides the electrical energy needed to create the arc. Power sources can be constant current (CC) or constant voltage (CV), depending on the welding process.

Electrodes:

Can be consumable or non-consumable, with various types and sizes depending on the specific welding process and material being welded.

Welding Gun or Electrode Holder:

Used to hold and control the electrode. In processes like GMAW and FCAW, the welding gun also delivers shielding gas.

Shielding Gas Supply:

Required for processes like GMAW and GTAW to protect the weld pool from contamination. Common gases include argon, helium, carbon dioxide, and mixtures.

Welding Cables:

Connect the power source to the electrode holder and workpiece.

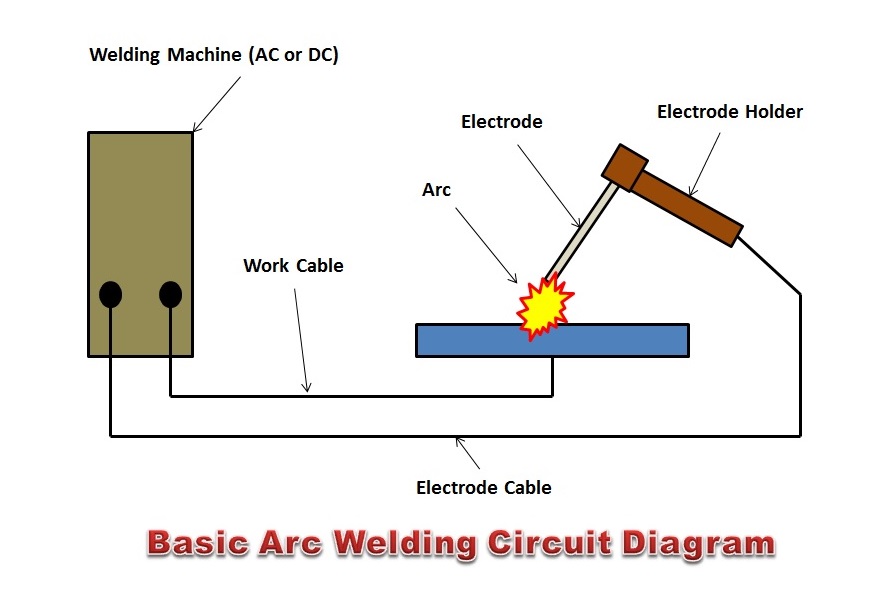

Basic Circuit Diagram of Arc Welding

The basic circuit diagram of arc welding is given below:

Step-by-Step Working of Arc Welding

Arc welding is a straightforward process once you understand the steps involved. Here’s a simple step-by-step guide to how arc welding works:

1. Preparation

Safety Gear:

- Wear appropriate personal protective equipment (PPE) such as a welding helmet with a proper shade, gloves, protective clothing, and safety boots.

Workspace Setup:

- Ensure the welding area is clean, dry, and free of flammable materials.

- Arrange for proper ventilation to avoid inhaling harmful fumes.

Equipment Check:

- Verify that all welding equipment is in good working condition, including the power source, cables, electrode holder, and shielding gas supply (if applicable).

2. Choosing the Electrode

Electrode Type:

- Select the correct electrode type for the material you are welding. For example, use a consumable electrode for stick welding or a non-consumable tungsten electrode for TIG welding.

Electrode Size:

- Choose the appropriate electrode size based on the thickness of the material and the welding current required.

3. Setting Up the Power Source

Power Source Connection:

- Connect the welding cables to the power source. One cable goes to the electrode holder, and the other to the workpiece or grounding clamp.

Adjusting Settings:

- Set the power source to the appropriate current and voltage based on the electrode type and material thickness. This might be constant current (CC) for stick and TIG welding or constant voltage (CV) for MIG welding.

4. Positioning the Workpiece

Securing the Workpiece:

- Position and secure the workpiece so it does not move during welding. Use clamps if necessary.

Grounding:

- Attach the grounding clamp to the workpiece or the welding table to ensure a complete electrical circuit.

5. Initiating the Arc

Striking the Arc:

- For stick welding: Strike the electrode against the workpiece like you would strike a match to initiate the arc.

- For TIG welding: Use a foot pedal or control to initiate the arc with the tungsten electrode.

- For MIG welding: Simply pull the trigger on the welding gun to start the arc.

6. Creating the Weld Pool

Maintaining the Arc:

- Keep the electrode at the correct distance from the workpiece (arc length). Too close, and it may stick; too far, and the arc may extinguish.

Forming the Weld Pool:

- Move the electrode or welding gun steadily along the joint, creating a molten weld pool. The speed and angle of travel affect the weld quality.

7. Adding Filler Material (if necessary)

Filler Material:

- In TIG welding, add filler metal to the weld pool by feeding a filler rod into the molten area as you move the torch.

- In stick and MIG welding, the electrode itself acts as the filler material.

8. Controlling the Weld

Weld Bead:

- Maintain a consistent speed and angle to produce an even weld bead. Watch the weld pool to ensure proper fusion of the base metals and the filler material.

Avoiding Defects:

- Adjust techniques to avoid common welding defects such as porosity, cracks, and spatter.

9. Finishing the Weld

Stopping the Arc:

- Gradually reduce the welding current (in processes that allow it) and lift the electrode away from the weld pool to stop the arc.

Post-Weld Care:

- Let the weld cool down naturally. Do not quench it with water as this can cause cracking.

- For processes that produce slag, such as stick welding, chip away the slag with a chipping hammer and brush the area clean.

10. Inspecting the Weld

Visual Inspection:

- Check the weld bead for uniformity, proper penetration, and any visible defects.

Testing:

- Depending on the application, additional tests such as x-ray, ultrasonic, or dye penetrant inspection may be required to ensure weld integrity.

Types of Arc Welding

1. Shielded Metal Arc Welding (SMAW):

Also known as stick welding, SMAW uses a consumable electrode coated with flux. The flux coating provides the necessary shielding by producing a gas when heated.

Commonly used for construction, repair, and maintenance work due to its simplicity and versatility.

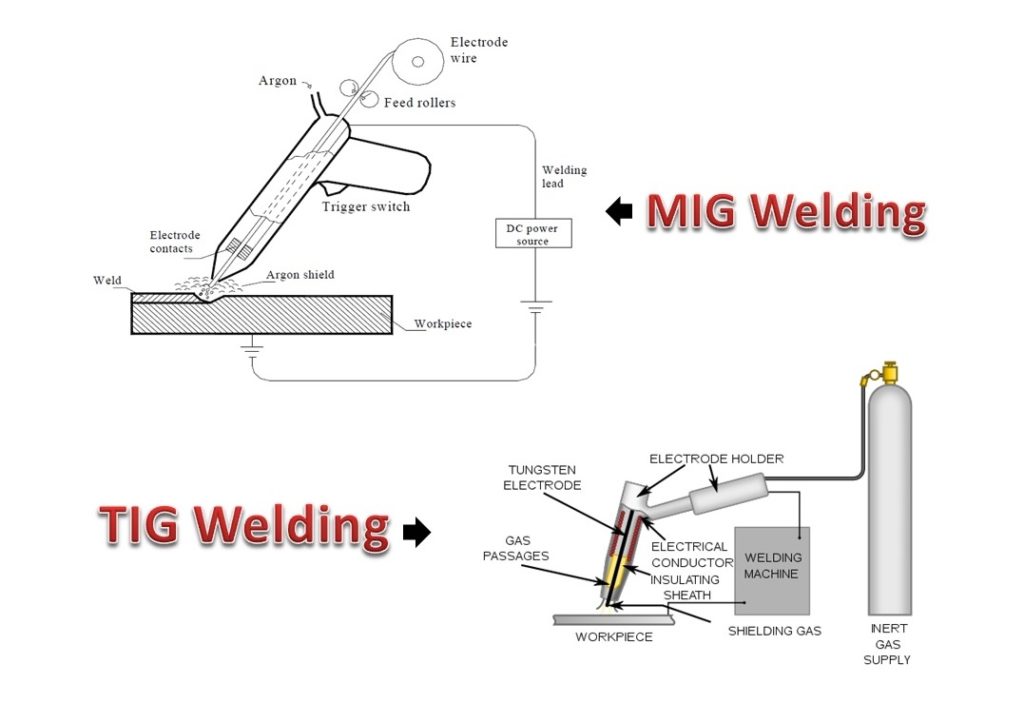

2. Gas Metal Arc Welding (GMAW):

Also known as MIG (Metal Inert Gas) welding, GMAW uses a continuous solid wire electrode fed through a welding gun. A shielding gas, typically argon or a mixture of gases, is also fed through the gun to protect the weld pool.

Popular in automotive and manufacturing industries for its speed and ease of automation.

3. Gas Tungsten Arc Welding (GTAW):

Also known as TIG (Tungsten Inert Gas) welding, GTAW uses a non-consumable tungsten electrode and an inert gas, usually argon, for shielding.

Known for producing high-quality, precise welds, it is commonly used in aerospace, piping, and fabrication of stainless steel and non-ferrous metals.

4. Flux-Cored Arc Welding (FCAW):

Similar to GMAW, but uses a tubular wire filled with flux. This method can be used with or without an additional shielding gas.

Ideal for heavy-duty applications such as shipbuilding, structural steel, and outdoor welding due to its ability to handle thicker materials.

5. Submerged Arc Welding (SAW):

Uses a consumable electrode and a blanket of granular flux to shield the weld. The arc is submerged beneath the flux layer, which prevents spatter and intense light.

Commonly used for welding thick steel plates in the manufacturing of pressure vessels, large pipes, and heavy machinery.

Also Read:

- What is Underwater Welding and How it works?

- Resistance Welding – Principle, Working and Application

- Friction Stir Welding – Working Principle, Advantages, Disadvantages with Application

Applications of Arc Welding

Arc welding is widely used across numerous industries due to its versatility and ability to produce strong, durable joints. Some common applications include:

- Construction: Welding of structural steel frameworks, bridges, and heavy machinery.

- Automotive: Manufacturing and repair of vehicle components, including chassis, exhaust systems, and body panels.

- Shipbuilding: Construction and repair of ships and offshore structures.

- Manufacturing: Fabrication of metal products, machinery, and equipment.

- Aerospace: Welding of aircraft components, both structural and non-structural.

Advantages and Disadvantages of Arc Welding

Arc welding is a widely used technique in metal fabrication due to its numerous benefits. However, like any technology, it also has its limitations. Understanding both the advantages and disadvantages of arc welding can help in choosing the right welding method for specific applications and in optimizing welding practices.

Advantages of Arc Welding

- Versatility:

- Arc welding can be used on a wide range of metals and alloys, including steel, stainless steel, aluminum, and cast iron.

- Suitable for various welding positions (flat, vertical, overhead, and horizontal).

- Strong and Durable Welds:

- Produces high-quality welds with excellent strength and durability, essential for structural applications.

- Cost-Effective:

- Equipment for basic arc welding is relatively inexpensive and widely available.

- Consumables like electrodes and filler metals are also generally affordable.

- Portability:

- Arc welding equipment, especially for SMAW (stick welding), is portable and can be used in remote locations without the need for complex infrastructure.

- Adaptability to Different Environments:

- Can be performed outdoors and in various environmental conditions, making it suitable for construction and fieldwork.

- Minimal Equipment Requirements:

- Basic arc welding processes do not require complex equipment. SMAW, for instance, only needs a power source, electrode holder, and consumable electrodes.

- Speed and Efficiency:

- Certain arc welding processes, like GMAW (MIG welding) and FCAW, offer high deposition rates, which speed up the welding process.

- Control and Precision:

- Processes like GTAW (TIG welding) allow for precise control over the weld, making them ideal for detailed and delicate work.

Disadvantages of Arc Welding

- Skill Requirement:

- Requires a high level of skill and expertise to produce consistent and high-quality welds.

- Proper training and experience are essential to avoid defects and ensure safety.

- Safety Hazards:

- Involves high temperatures, intense ultraviolet and infrared radiation, and potentially hazardous fumes.

- Proper protective gear and safety measures are necessary to prevent burns, eye damage, respiratory issues, and electric shock.

- Post-Weld Cleaning:

- Some arc welding processes, such as SMAW, produce slag that needs to be chipped away and cleaned after welding.

- Limited to Conductive Materials:

- Only conductive materials can be welded using arc welding processes, limiting its use with some non-metals and composites.

- Heat Distortion:

- The high heat input can cause warping or distortion of the base materials, particularly in thin sections.

- Equipment Maintenance:

- Welding equipment and consumables require regular maintenance and proper handling to ensure consistent performance and safety.

- Environmental Concerns:

- Generates fumes and gases that can be harmful to both the environment and the welder’s health if not properly ventilated.

- Energy Consumption:

- High energy consumption can lead to increased operational costs, especially in industrial-scale welding applications.

Safety Considerations

Arc welding involves high temperatures, intense light, and hazardous fumes, making safety a critical concern. Key safety measures include:

- Protective Gear: Welders should wear appropriate personal protective equipment (PPE), including a welding helmet with a proper shade, gloves, protective clothing, and safety boots.

- Ventilation: Ensure adequate ventilation to avoid inhaling harmful fumes and gases produced during welding.

- Fire Prevention: Keep flammable materials away from the welding area and have fire extinguishing equipment readily available.

- Electrical Safety: Use insulated tools and equipment, and ensure proper grounding of the welding setup to prevent electric shock.

- Training: Proper training and certification are essential to ensure safe and effective welding practices.

Conclusion

Arc welding is a fundamental technique in metal fabrication, offering versatility, strength, and efficiency in joining metals. By understanding its principles, types, equipment, applications, and safety measures, welders can ensure high-quality welds and maintain a safe working environment. Whether you’re a professional welder or an enthusiast, mastering arc welding opens up a world of possibilities in metalworking.