Introduction

Flux cored arc welding (FCAW) is a semi-automatic or automatic arc welding process. It requires a continuously fed tubular electrode containing a flux and a constant current welding power supply. That is FCAW uses a tubular wire that is filled with a flux. The arc is started from the electrode to the job. The flux which is filled in the electrode melts during the welding process and shields the welded area from the atmosphere.

DCEP (direct current, electrode positive) is commonly employed in FCAW.

Main Equipment:

1. Power Source

- Most power sources operate on 230 or 460 volts input power but machines that operate on 200 to 575 volts input are also available.

- It may operate either on a single or three-phase input frequency of 50 -60 hertz.

- Most power sources used for flux-cored arc welding have a 100% duty cycle i.e. they can be used continuously.

2. Wire Feed Motor

A wire feed motor provides power for driving the electrode through the cable and given to the workpiece. Most of the wire feed systems are used for FCAW are the constant speed type which are used with a constant voltage power source.

A wire feed consists of an electrical rotor connected to a gearbox.

3. Air and Water Cooled Guns:

(i) Air-Cooled Guns: Air-cooled welding guns are cooled primarily by the surrounding air but a shielding gas when used provides a better cooling effect.

(ii) Water-Cooled Guns: A water-cooled welding gun has ducts to allow water to circulate around the contact tube and the nozzle.

The guns which are preferred according to the conditions are as follows:

- Above 500 Amp: Water-cooled gun

- Below 500 Amp: Air-cooled gun

4. Shielding Gases

- Shielding gas equipment is used for shielded flux cored wires consist of a gas supply hose, a gas regulator, and a control valve. The shielding hose is connected to the welding gun.

- Shielding gas is used to protect the welded area from the atmosphere and other gases like oxygen and nitrogen.

- Some shielding gases are carbon dioxide, argon mixed with carbon dioxide, argon-oxygen mixture.

5. Electrode

It uses consumable types of electrodes. The electrodes used for FCAW provide the filler metal to the weld puddle.

Also Read:

- Top 8 Advantages of arc Welding

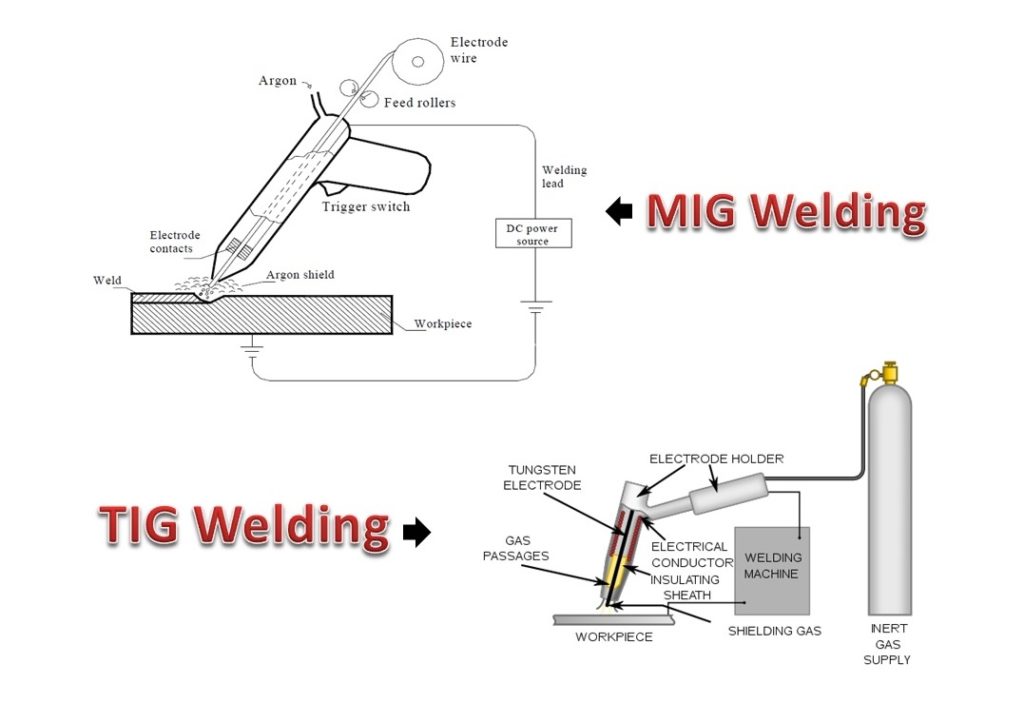

- Difference Between MIG and TIG Welding

- Types of Welding Process – Everyone Should Know

Working of Flux Cored Arc Welding

Flux cored arc welding or tubular electrode welding has evolved from the MIG welding process to improve arc action, metal transfer, etc. Some steps are as follows:-

- In this type of arc welding process, the heat for welding is provided by an arc between a continuously fed tubular electrode and the workpiece.

- Shielding is obtained by a flux which is contained inside the electrode.

There are basically 2 types of flux-cored arc welding processes:-

- Self-shielded FCAW(without shielding gas)

- Gas shielded FCAW(with shielding gas)

The difference in the two processes is due to the different fluxing agents in the consumables.

- Self-shielded FCAW(Without Shielding Gas):

- The fluxing agent in self-shielded FCAW is used in outdoor conditions where there is a chance that the wind may take away the shielding gas.

- The fluxing agent in self-shielded FCAW is designed to not only deoxidize the weld pool but also to allow the metal droplets and the pool keep away from the atmosphere.

- Gas shielded FCAW (With Shielding Gas)

- The flux in gas-shielded FCAW provides deoxidation of the weld pool to a smaller degree as compared to self-shielded FCAW.

- The flux is designed to support the weld pool for out of position welds to increase productivity for deeper penetration.

Also Read:

- Plasma Arc Welding Process- Principle, Main Parts, Working, Advantages and Disadvantages with Application

- What is Seam Welding and How it Works?

- Different Types of Welding Joints

Advantages of Flux cored Arc Welding

- FCAW may be an all position process.

- No shielding gas needed for some wires suitable in windy conditions.

- Less cleaning of metal is required.

- Porosity chances are very low.

- High deposition rate.

Disadvantages:

- The slag must be removed.

- More smoke comes out as compared to other processes like GMAW and SAW.

- Spatter is more.

- The wire is more expensive.

- Equipment is expensive and complex.

Application:

- Used in the shipbuilding industry as this saves huge labor costs.

- Frequently used in construction industries for welding.

In this article, we have learned about flux cored arc welding process. if you find this article interesting and useful then don’t forget to share it.