Welding is one of the most essential skilled trades in the United States, supporting industries such as construction, automotive manufacturing, shipbuilding, oil & gas, and aerospace. However, welding is also one of the most hazardous industrial jobs if proper safety rules are not followed.

In this complete, USA-focused guide, you’ll learn the mandatory welding safety rules in the USA, based on federal regulations, industry standards, and real-world best practices. Whether you are a beginner welder, certified professional, workshop owner, or employer, this guide is designed to help you stay safe, compliant, and productive.

Why Welding Safety Rules Are Critical in the USA

Welding exposes workers to multiple hazards at the same time:

- Extreme heat and molten metal

- Intense UV and infrared radiation

- Toxic welding fumes and gases

- Electric shock risks

- Fire and explosion hazards

According to workplace safety data in the U.S., thousands of welding-related injuries occur every year—many of them completely preventable by following established safety rules.

In the USA, welding safety is not optional. It is governed by federal law and enforced through inspections, penalties, and workplace compliance audits.

Who Regulates Welding Safety in the USA?

Welding safety in the United States is primarily regulated and guided by:

- Occupational Safety and Health Administration (OSHA)

- American Welding Society (AWS)

- American National Standards Institute (ANSI)

OSHA regulations are legally mandatory, while AWS and ANSI standards are widely adopted as industry best practices and often referenced by OSHA during inspections.

OSHA Welding Safety Standards You Must Know

OSHA welding safety rules are mainly covered under:

- 29 CFR 1910 Subpart Q – Welding, Cutting, and Brazing

- 29 CFR 1910 Subpart I – Personal Protective Equipment

- 29 CFR 1910.252–255 – Arc welding, gas welding, and cutting

Failure to comply can result in heavy fines, work stoppages, or legal action.

Personal Protective Equipment (PPE) for Welders (Mandatory)

Required PPE for Welding in the USA

Every welder must wear appropriate PPE to protect against burns, radiation, fumes, and impact injuries.

Essential welding PPE includes:

- Welding helmet with proper lens shade (ANSI Z87.1 compliant)

- Flame-resistant (FR) welding clothing

- Welding gloves

- Safety glasses with side shields (under the helmet)

- Steel-toe welding boots (ASTM-compliant)

- Welding apron or jacket

- Ear protection when required

Welding Helmet Shade Requirements

OSHA recommends lens shades based on welding current. Using the wrong shade can cause arc eye (welder’s flash) and permanent eye damage.

Ventilation and Fume Control Rules

Why Welding Fumes Are Dangerous

Welding fumes may contain:

- Hexavalent chromium

- Manganese

- Zinc oxide

- Carbon monoxide

- Nitrogen oxides

Long-term exposure can cause lung damage, metal fume fever, and neurological issues.

OSHA Ventilation Requirements

- Local exhaust ventilation is required in enclosed spaces

- Respirators must be used when ventilation is insufficient

- Confined space welding requires air monitoring and permits

Proper fume extraction is not optional under U.S. law.

Fire Prevention and Explosion Safety Rules

Fire Safety Rules Every Welder Must Follow

- Remove flammable materials within 35 feet

- Use fire-resistant welding blankets

- Keep fire extinguishers nearby

- Assign a trained fire watch when required

- Never weld near explosive containers

Hot Work Permit System

Many U.S. workplaces require a Hot Work Permit before welding. This permit ensures:

- Hazard assessment

- Fire prevention measures

- Supervisor authorization

Electrical Safety Rules for Arc Welding

Electric shock is one of the leading causes of welding fatalities.

OSHA Electrical Safety Rules

- Inspect welding cables daily

- Replace damaged insulation immediately

- Ensure proper grounding

- Keep hands and gloves dry

- Never weld in wet conditions

Even low-voltage welding equipment can be fatal under the wrong conditions.

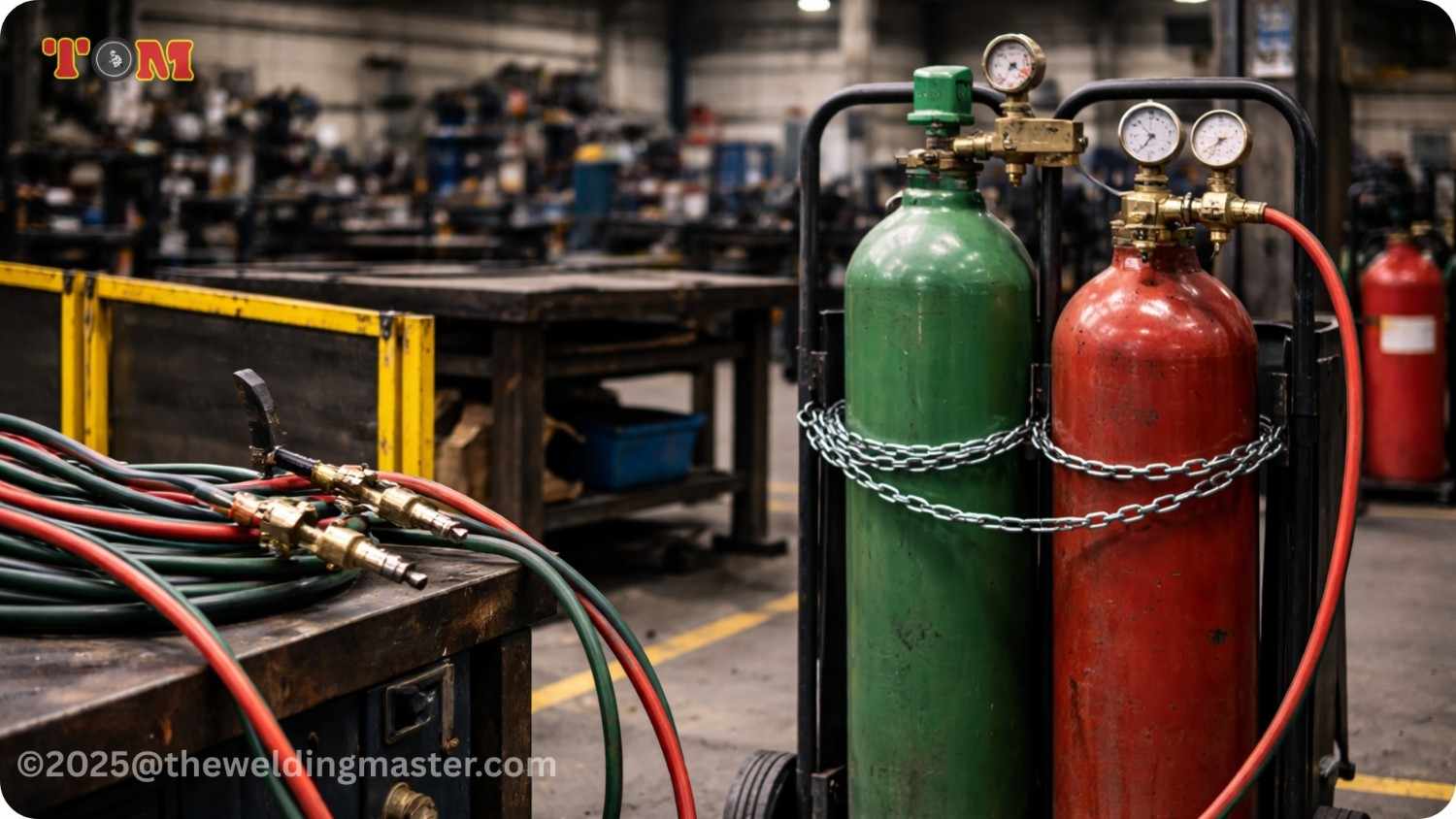

Gas Welding and Cylinder Safety Rules

Oxygen and Fuel Gas Cylinder Rules

- Secure cylinders upright at all times

- Store oxygen and fuel gases separately

- Use flashback arrestors

- Never use oil or grease on oxygen fittings

- Close valves when not in use

Improper gas handling can lead to violent explosions.

Confined Space Welding Safety Rules

Confined spaces include tanks, pipelines, vessels, and enclosed rooms.

Mandatory Safety Measures

- Confined space permit

- Continuous air monitoring

- Ventilation systems

- Trained standby personnel

- Emergency rescue plan

Confined space welding deaths are often caused by asphyxiation, not burns.

Training and Certification Requirements in the USA

OSHA Training Rules

OSHA requires that welders be:

- Properly trained

- Competent in equipment use

- Aware of hazards

Industry Certifications

While OSHA does not mandate certification, employers often require:

- AWS Certified Welder

- Employer qualification tests

- Safety training documentation

Employer Responsibilities Under U.S. Law

Employers must:

- Provide PPE at no cost

- Maintain safe equipment

- Conduct safety training

- Enforce safety rules

- Maintain safety records

Failure to comply can result in OSHA citations and penalties.

Common Welding Accidents and How to Prevent Them

| Accident Type | Cause | Prevention |

| Arc eye | No eye protection | Proper helmet shade |

| Burns | Exposed skin | FR clothing |

| Electric shock | Poor grounding | Equipment inspection |

| Fires | Sparks near flammables | Fire watch |

| Fume inhalation | Poor ventilation | Fume extraction |

Welding Safety Checklist (USA Standard)

- PPE worn correctly

- Equipment inspected

- Ventilation active

- Fire extinguisher available

- Area free of flammables

- Proper supervision

Final Thoughts: Welding Safety Is Not Optional in the USA

Following welding safety rules in the USA is about more than compliance—it’s about protecting lives, careers, and businesses. Whether you’re a solo welder or managing a large fabrication shop, strict adherence to safety standards ensures long-term success and legal protection.

Frequently Asked Questions (FAQs)

1. Are welding safety rules mandatory in the USA?

Yes. OSHA welding safety rules are federal law. Employers and welders must comply to avoid fines, injuries, or shutdowns.

2. What PPE is legally required for welding in the USA?

At minimum: welding helmet, safety glasses, flame-resistant clothing, gloves, and protective footwear.

3. Is ventilation mandatory during welding?

Yes. OSHA requires adequate ventilation or respiratory protection when welding fumes exceed exposure limits.

4. Can I weld without certification in the USA?

Legally yes, but employers often require AWS or internal certification for safety and quality compliance.

5. What is a Hot Work Permit?

A Hot Work Permit is a written authorization required before welding in fire-prone or hazardous areas.

6. Is welding in confined spaces allowed?

Yes, but only with permits, ventilation, air monitoring, and trained safety personnel.

7. What happens if OSHA welding rules are violated?

Violations can result in fines, legal action, project shutdowns, or criminal liability in severe cases.

8. Are welding fumes harmful long-term?

Yes. Long-term exposure can cause lung disease, neurological disorders, and cancer depending on materials welded.

9. Who enforces welding safety in the USA?

OSHA enforces federal welding safety laws, often referencing AWS and ANSI standards.

10. Do small workshops need to follow OSHA welding rules?

Yes. OSHA rules apply to businesses of all sizes in the USA.