If you are new to welding, choosing between Stick, MIG, and TIG welding can feel overwhelming. Every beginner hears different advice. Some say Stick welding makes you a “real welder,” others recommend MIG as the easiest way to start, while TIG is often praised as the most advanced and professional option.

So the real question is simple:

Which welding process should you learn first?

As a welding instructor with more than 15 years of hands-on experience, this guide gives you the honest, practical answer based on safety, learning curve, real-world usability, and long-term career value. This article is written for beginner welders, DIY hobbyists, trade students, and career-focused learners who want clarity instead of confusion.

By the end, you will know exactly which welding method is best for you to start with and why.

Which Welding Should a Beginner Learn First?

For most beginners, MIG welding is the best welding process to learn first.

It has the easiest learning curve, produces clean welds, requires less coordination, and works perfectly for home projects and entry-level welding jobs. Stick welding is better suited for outdoor and construction work, while TIG welding is best learned later due to its higher difficulty and precision requirements.

Understanding the Three Main Welding Types

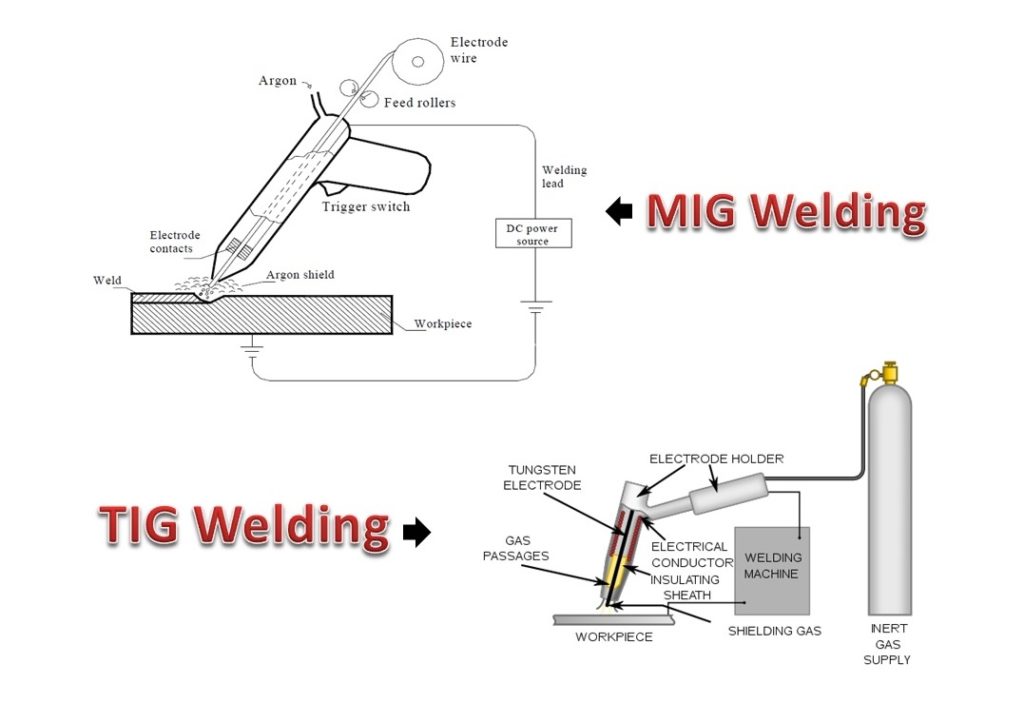

Before comparing them, it helps to understand what each welding process actually involves.

- Stick Welding (SMAW): Uses a consumable electrode coated in flux to create the weld and shielding.

- MIG Welding (GMAW): Uses a continuously fed wire and shielding gas for clean, consistent welds.

- TIG Welding (GTAW): Uses a tungsten electrode and a separate filler rod for high-precision welding.

All three are widely used in the welding industry, but they are not equally beginner-friendly.

Stick Welding Explained (SMAW)

How Stick Welding Works

Stick welding uses a flux-coated electrode that melts to form the weld while producing a protective gas shield. The welder strikes an arc and manually controls the rod as it burns down.

This method is rugged, reliable, and still heavily used in industrial work.

Difficulty Level for Beginners

Stick welding has a moderate to high learning difficulty.

Beginners often struggle with:

- Maintaining correct arc length

- Preventing the rod from sticking

- Producing smooth, consistent weld beads

Equipment and Setup Requirements

- Stick welding machine

- Welding electrodes such as 6011, 6013, or 7018

- Welding helmet, gloves, and jacket

- No shielding gas required

Stick welding equipment is affordable and highly portable.

Best Real-World Applications

- Outdoor welding

- Construction sites

- Farm repairs

- Structural steel work

Common Beginner Mistakes

- Sticking the electrode repeatedly

- Uneven bead appearance

- Poor slag removal

- Choosing the wrong electrode type

Stick welding builds strong fundamentals, but beginners often find it frustrating at first.

MIG Welding Explained (GMAW)

How MIG Welding Works

MIG welding uses a wire-fed gun that continuously feeds electrode wire while shielding gas protects the weld pool. You simply pull the trigger and guide the gun.

This simplicity is why MIG welding is widely considered the easiest welding process to learn.

Difficulty Level for Beginners

MIG welding has a low difficulty level and is extremely beginner-friendly.

It eliminates many challenges beginners face:

- No rod changes

- Easier arc control

- Cleaner welds with less spatter

Many beginners produce acceptable welds on their very first day.

Equipment and Setup Requirements

- MIG welding machine

- Welding wire spool

- Shielding gas cylinder

- Standard welding safety gear

The upfront cost is higher than Stick welding, but the learning curve is much faster.

Best Real-World Applications

- Home garage projects

- Automotive repairs

- Fabrication shops

- Thin to medium steel welding

Common Beginner Mistakes

- Incorrect voltage or wire speed settings

- Poor joint preparation

- Wrong gun angle

- Welding outdoors in windy conditions

MIG welding is one of the fastest ways for beginners to build confidence.

TIG Welding Explained (GTAW)

How TIG Welding Works

TIG welding uses a tungsten electrode to create the arc while the welder feeds filler rod by hand. Shielding gas protects the weld from contamination.

This process offers unmatched precision and control.

Difficulty Level for Beginners

TIG welding has a high learning difficulty.

It requires:

- Two-hand coordination

- Precise torch control

- Careful heat management

Equipment and Setup Requirements

- TIG welding machine

- Tungsten electrodes

- Filler rods

- Argon shielding gas

- Advanced safety gear

TIG welding has the highest setup cost and steepest learning curve.

Best Real-World Applications

- Aerospace welding

- Stainless steel fabrication

- Aluminum welding

- High-end custom projects

Common Beginner Mistakes

- Contaminating the tungsten electrode

- Poor filler rod control

- Overheating the base metal

- Inconsistent torch movement

TIG welding is extremely rewarding, but it is not beginner-friendly.

Stick vs MIG vs TIG Welding: Beginner Comparison

When comparing stick vs MIG vs TIG welding, beginners should focus on learning difficulty, equipment cost, speed of learning, and real-world usability.

| Comparison Factor | Stick Welding | MIG Welding | TIG Welding |

| Learning Difficulty | Moderate | Easiest | Hardest |

| Cost of Equipment | Lowest upfront cost | Mid-range | Highest |

| Speed of Learning | Moderate | Fastest | Slow |

| Indoor vs Outdoor Use | Excellent outdoors | Best indoors | Indoor only |

| Career Relevance | Construction, pipelines | Manufacturing, fabrication | Aerospace, specialty welding |

Pros and Cons of Each Welding Method

Stick Welding Pros and Cons

Pros

- Works well outdoors

- Low equipment cost

- Strong, durable welds

- Widely used in heavy industry

Cons

- Steeper learning curve

- Slag cleanup required

- Less clean appearance

MIG Welding Pros and Cons

Pros

- Best welding for beginners

- Clean and consistent welds

- Fast learning curve

- High productivity

Cons

- Not ideal for windy outdoor use

- Requires shielding gas

- Slightly higher upfront cost

TIG Welding Pros and Cons

Pros

- Highest weld quality

- Excellent precision

- Works on many metals

Cons

- Hardest welding process to learn

- Slow welding speed

- Expensive equipment

Which Welding Process Is Best Based on Beginner Goals?

- Best welding for beginners: MIG welding

- Best for outdoor and construction work: Stick welding

- Best for precision and advanced careers: TIG welding

DIY and Home Garage Beginners

MIG welding is ideal because it is easy to learn, produces clean welds, and works well for common home projects.

Career-Focused Welders

Start with MIG welding to build fundamentals, then move to Stick welding for structural work, and TIG welding for precision and higher-paying specialties.

Outdoor and Construction Work

If your goal is job-site welding or outdoor repairs, Stick welding may be the better first choice, even though it takes longer to master.

You can Also buy these books to enhance you welding knowledge : Best welding books for Welders

Learning Timeline: What to Expect

First 30 Days

- MIG: Learn basic beads and simple joints

- Stick: Practice arc control and rod handling

- TIG: Focus on torch control and heat management

90 Days

- MIG: Produce consistent beginner-level welds

- Stick: Improved bead control and confidence

- TIG: Slow but steady progress

180 Days

- MIG: Job-ready for basic fabrication

- Stick: Confident on structural welds

- TIG: Controlled welds on thin materials

Career and Long-Term Value

Industry Demand

- MIG welders are in constant demand in manufacturing and fabrication

- Stick welding is essential in construction and pipeline work

- TIG welders earn premium pay in aerospace and specialty fields

Skill Transferability

Learning MIG welding first helps beginners understand puddle control, heat management, and joint preparation. These skills transfer easily to Stick and TIG welding later.

Conclusion

If you are just starting out, begin with MIG welding to build confidence and strong fundamentals. Add Stick welding for outdoor and structural work, then learn TIG welding for precision and higher-paying specialties.

Welding rewards patience, practice, and smart learning choices. Start simple, stay safe, and build your skills step by step.

FAQs: Frequently Asked Questions

Which welding is best for beginners?

MIG welding is the best option for beginners because it is easy to learn and produces clean, consistent welds.

Is Stick welding harder than MIG?

Yes, Stick welding has a steeper learning curve due to arc control and slag management.

Is TIG welding worth learning?

Yes, TIG welding is extremely valuable, but it is best learned after MIG or Stick welding.

Can I learn welding at home?

Yes, with proper safety equipment, training, and consistent practice.

How long does it take to become a welder?

Basic welding skills can be learned in a few months, while professional mastery takes years.

Should I buy a welder before learning?

Yes, starting with a beginner-friendly MIG welder is strongly recommen